- Sustainable Effluent Management

All of our tankers are fitted with large flotation tyres that are excellent at distributing load weight and minimising soil compaction, but if you are concerned that your soil is particularly soft, the single axle tanker is a great choice. They may have a smaller capacity, but that reduced weight and the shorter wheelbase make them easy to manoeuvre in tight spaces. Although you’d be surprised to find out how well our bigger slurry tankers handle, as they all have steering axles. The single axle tanker is also the right choice if your tractor doesn’t have the horsepower to pull a bigger load. You’ll need 80hp – 100hp, depending on the model you choose.

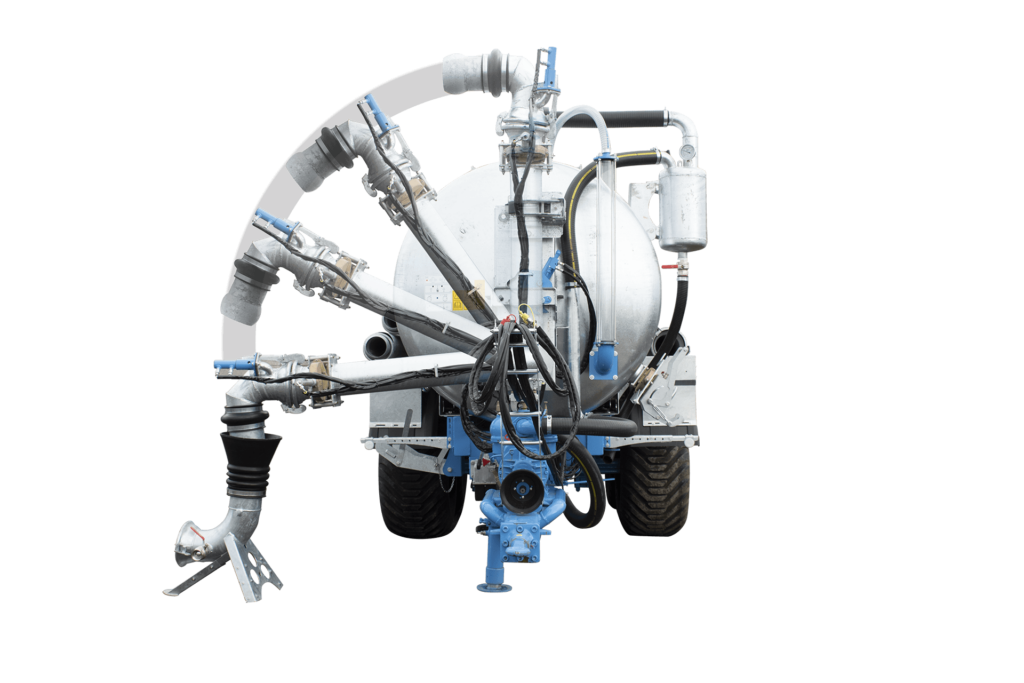

Every Nevada Slurry Tanker comes with a RainWave™ effluent applicator as standard, and owners enthuse about the performance.

The Nevada RainWave™ is an oscillating system that is self-driven – there is no hydraulic or electric drive, it simply oscillates from side to side. This simplicity delivers a nice wide and even spread of effluent across the paddock. As the system oscillates, large droplets fall through the grass/crop onto the ground surface. The immediate benefit is virtually no wind drift issues or volatilisation of nitrogen disappearing into the atmosphere, with minimal smell or odour. It also gives you very precise control and accurate spreading, so you can reach every corner of your farm.

Galvanising is the only way to provide corrosion protection over the entire tank, including the joints. All Nevada tanks are hot-dip galvanised inside and out. This ensures every crevice is protected from corrosion. A clear coat is then applied on the exteria to slow oxidisation. Anti-implosion rings are welded to the tank skin prior to rolling, creating a more accurate and perfect circle.

Nevada’s tanks are made from quality European S235JR steel, a non-alloy structural steel coated to ASTM A123. S235JR steel is widely used for machine building and is ideal for slurry tanks as it is strong while being able to be rolled, welded, and hot-dip galvanised for protection.

Nevada slurry tankers go through a special manufacturing process where the submerged arc welded to the steel plates before the tank is rolled. This adds strength by creating a tank made from one piece so that there is no separation or areas where rust can form.

All Nevada Slurry Tankers come standard with heavy-duty Italian Battioni vacuum pumps, built to handle the demands of dairy farming. These PTO-driven pumps are well-suited for thick slurries and offer reliable performance across a wide range of applications.

The standard pumps for 6,000-8,200L tanker models include long life vanes, and a long duty cycle providing a reliable and low maintenance operation ample for slurry tankers of this size/capacity.

Standard vacuum pumps on 10,000L tanker models include long life vanes and are also air injected with integrated crash protection (ICP), and an even further increased duty cycle. Given the increased size, and therefore usage requirements of larger tankers, these vacuum pumps are designed for a duty cycle of 70%.

Nevada Single Axle Slurry Tankers are built with a drawbar incorporating multi-leaf spring suspension to absorb shock loading, protecting the tractor and driver from stress and fatigue

This is a fantastic safety feature on every tanker. Each wheel is connected to a large hydraulic braking system to ensure a safe and reliable operation, as well as a manual park brake. This gives you much more control on slopes and inclines.

These huge tyres offer more safety on rolling terrain and reduce soil compaction as the greater surface area spreads the load. They are longer-lasting, with a high resistance to puncture. Different sizes available on request.

Combine this 8 inch Auto-Fill Arm with the Nevada Ezi-load system and filling up the tank is a breeze. From the comfort of your tractor seat, all you have to do is align the auto-filling arm with the large pond-side filling station. Just drop it in and the pump does all the work.

Loading time depends on the size of the slurry tanker and pump capacity, but the Ezi-load will typically take only a few minutes to completely fill the tank. The arm is then lifted (again from the tractor seat) and the slurry tanker is ready to go and begin spreading across the entire farm. It makes the whole process of spreading effluent fast and efficient.

Nevada slurry tankers & stirrers are high-quality and trusted by New Zealand farmers for safety and reliability. That is why they are supported with a two year warranty, and backed by customer service that is second to none.

Discover engaging videos and media showcasing our equipment, success stories, and best practices in dairy effluent management.

GET IN TOUCH

Take the next step toward efficient, sustainable dairy farming with Nevada Group’s expert solutions.

Access valuable resources, expert advice, and tools to optimise your dairy farm’s effluent management.

Stay ahead with the latest in dairy effluent management. Our expert blogs cover best practices, product insights, sustainability…

Discover engaging videos and media showcasing our equipment, success stories, and best practices in dairy effluent management.

Explore our full range of dairy effluent solutions in one place. Download our catalogues to browse top-quality equipment, innovative solutions, and…

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields