- Sustainable Effluent Management

With so many more advantages for carrying the weight, triple axle slurry tankers 18,250L+ are by far the most cost effective option. Ideal for contractors or if you’ve got large or multiple farms, triple axle tankers with duo RainWave™ provide fast application for large loads.

Tractors above 200hp will have no trouble pulling these slurry tankers. Steering axles ensure they’re very manoeuverable, and with six wheels on the ground there’s a lot less ground pressure, making them suitable on flat and gentle rolling land.

Nevada’s larger range of Tankers, the Triple Axle series come fitted with a Duo RainWave™. Offering a more controlled and larger a 20 metre spread width, plus creating a fast and efficient unload time, so you can easily go back and grab the next load. Not sure if a RainWave™ or a splash plate is the best fit for your set-up? Check out the comparrison blog here.

Galvanising is the only way to provide corrosion protection over the entire tank, including the joints. All Nevada tanks are hot-dip galvanised inside and out. This ensures every crevice is protected from corrosion. A clear coat is then applied on the exteria to slow oxidisation. Anti-implosion rings are welded to the tank skin prior to rolling, creating a more accurate and perfect circle.

Nevada’s tanks are made from quality European S235JR steel, a non-alloy structural steel coated to ASTM A123. S235JR steel is widely used for machine building and is ideal for slurry tanks as it is strong while being able to be rolled, welded, and hot-dip galvanised for protection.

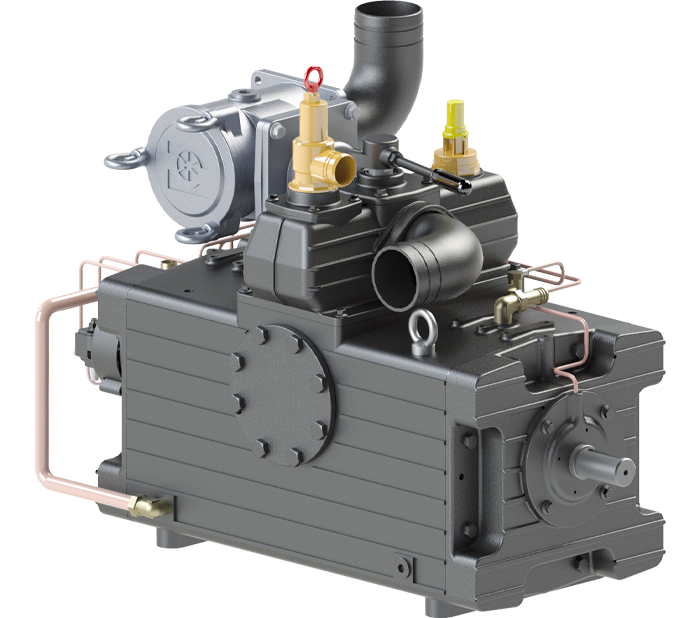

All Nevada Triple Axle Slurry Tankers up to and including the 22,200L are fitted with a Battioni Ballast 16500MA vacuum pump that has long-life vanes, air injection, and Integrated Crash Protection (ICP) to safeguard internal components. With a reinforced build and enhanced features, this vacuum pump is engineered for an extended 70% duty cycle.

Nevada 25,000L and up triple axle slurry tankers are fitted with a Battioni KTS 1080 Vacuum Pump. The KTS design provides maximum performance by offering both water and air injected cooling systems, giving the KTS range a near continuous duty cycle of 95%. In the event of a vane crash, the KTS Crash Protection System prevents damage to the housing or rotor, allowing for quick and cost-effective repairs.

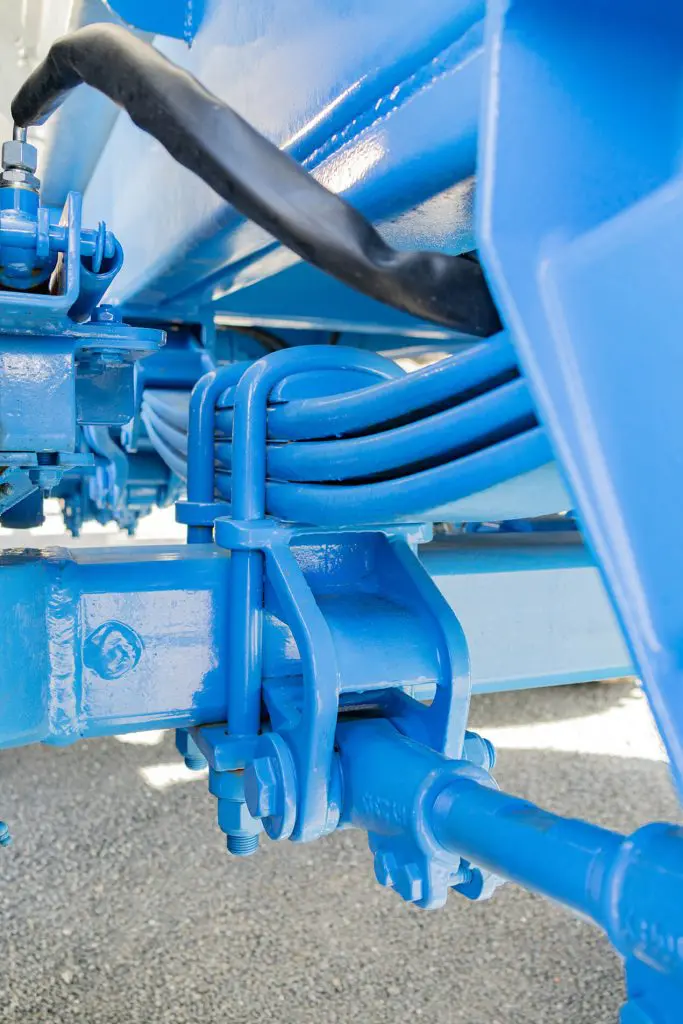

On Nevada triple axle slurry tankers up to 25,000L, leaf suspension on all axles provides a tough yet simple system that improves comfort and reduces stress on both the machine and tractor—especially when working over rolling or uneven ground.

To back that up, hydraulic drawbar suspension also comes standard on every Nevada triple axle tanker, giving you a smoother, more reliable ride.

For the biggest machines, hydraulic suspension comes standard on all slurry tankers 30,800L and above, giving you maximum stability and comfort when carrying heavy loads.

Triple axle tankers include large hydraulic braking on every wheel to ensure a safe and reliable operation, as well as a manual park brake.

Triple axle tankers are built with floating steering system with a hydraulic lockout, providing easy turning for manouverability around the farm, especially through tight gateways and creating less ground damage.

On Nevada slurry tankers 20,150L and above, the Loading Accelerator comes as standard. This clever feature speeds up filling by as much as 30%, getting you back out spreading faster. By forcing the effluent into the tank, it requires less vacuum suction, which also means less foaming. It’s especially handy when dealing with thick slurry, such as what you’d get from slatted floor cow barns.

With the addition of the load accelerator, the HydraHub control system is standard on all Nevada Triple Axle Slurry Tankers. Designed for situations where several hydraulic points are required, the HydraHub keeps everthing simple and efficient. Whether you’re running different applicators, adjusting flow, or switching between spreading methods, HydraHub ensures smooth operation for all your effluent applications.

Nevada slurry tankers & stirrers are high-quality and trusted by New Zealand farmers for safety and reliability. That is why they are supported with a two year warranty, and backed by customer service that is second to none.

Discover engaging videos and media showcasing our equipment, success stories, and best practices in dairy effluent management.

GET IN TOUCH

Take the next step toward efficient, sustainable dairy farming with Nevada Group’s expert solutions.

Access valuable resources, expert advice, and tools to optimise your dairy farm’s effluent management.

Stay ahead with the latest in dairy effluent management. Our expert blogs cover best practices, product insights, sustainability…

Discover engaging videos and media showcasing our equipment, success stories, and best practices in dairy effluent management.

Explore our full range of dairy effluent solutions in one place. Download our catalogues to browse top-quality equipment, innovative solutions, and…

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields