- Sustainable Effluent Management

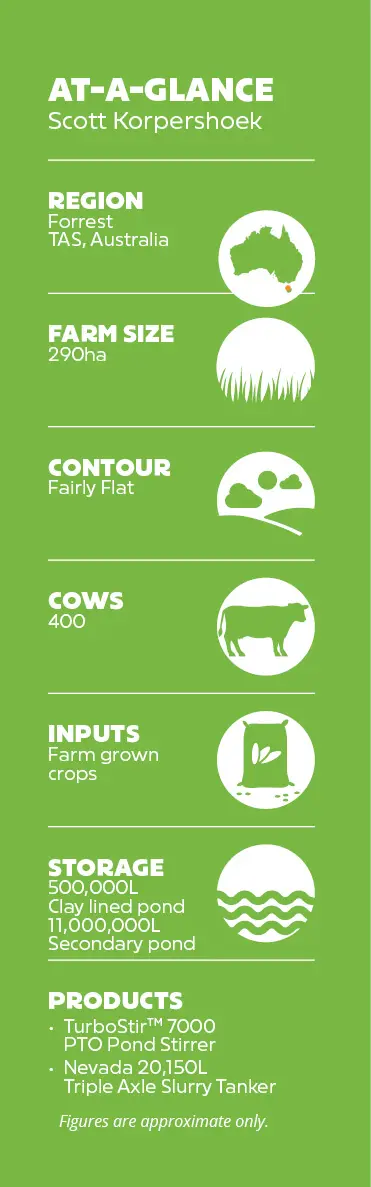

Scott and his family have a 290-hectare farm near Stanley in Tasmania. This is a mixed operation. They run 400 dairy cows, grow some potatoes, onions and crops to support the cows, and that keeps them pretty busy.

Originally, he had a separation system at the cowshed and a direct irrigation system off that, which wasn’t the best system. He had to shift sprinklers every few days to make sure areas didn’t get flooded. It was just a problem he’d rather not have. He’d bring in contractors once a year to empty the pond but he knew that wasn’t the most efficient way to deal with his effluent. The system did its job, but didn’t work well for the farm. Once they put a new feedpad in and started collecting more effluent, they knew they needed to upgrade their system.

What Scott realised was that he could turn this effluent problem into a fertiliser solution and use this resource across the whole farm. Scott and his family invested in a Nevada PTO pond stirrer and a 20,000L triple axle slurry tanker. It took about four to five weeks to arrive from New Zealand, and then they were good to go. Initially, he wasn’t sure what size tanker to go with but was very happy he went with the bigger option. He has another farm and contracts out the tanker to his neighbours, so it was a good decision.

He knew that effluent was full of potassium and phosphorus and great for soil health and growth, but he didn’t realise how much. One of the first times he went with the slurry tanker to pre-spread a maize field, he missed some corners in the paddock’s headland. His father gave him some grief about that, but once the maize had grown, it was plain to see where the slurry had been used. The maize reached eight to nine feet in the main part of the paddock but only reached six feet in the corners where he’d missed – nearly a metre difference.

Using the slurry tanker has been simple; the steering axles and brakes make it easy to get around the farm and the big baffles mean there is no sloshing around. Scott particularly likes the Duo Rainwave™ guns on the tanker for their accuracy of application. He can get to every part of the farm, and there is less odour.

Mccauley Carse (Macca) is a mechanic and operator on the farm and is responsible for spreading, so he uses the slurry tanker most often. He’s a huge fan. He likes that he can easily hook up the PTO stirrer, back it up to the pond, set the revs to 540 and it chops through the effluent. He then gets the tanker, drops the chute and fills the 20,000 litres in about four to five minutes. No messing around, he can spread several loads in a day. They follow the cows as they leave the paddocks, and they now have a very efficient rotation system in place, where they are getting maximum value from their effluent.

There is always going to be a challenge with effluent but now Scott looks at it in a different light. It is no longer an issue; it is a resource that he has been able to capitalise on. With the slurry tanker, he has been able to get around the whole farm, feeding the soil and using the effluent when it has the highest concentration of nutrients. He’s saving money on pre-spread synthetic fertiliser and his farm is reaping the benefits.

CASE STUDIES

Bringing you helpful advice, info, news and stories from Nevada. See how Nevada Group’s solutions have transformed dairy farms with increased efficiency and sustainability.

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields