- Sustainable Effluent Management

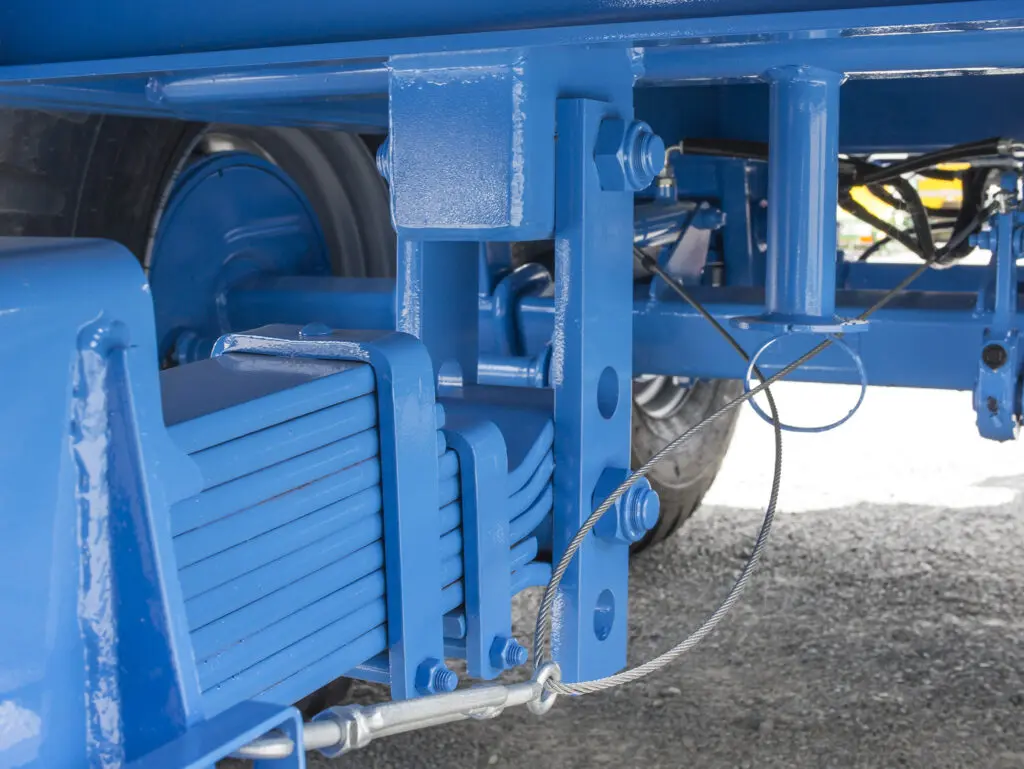

Nevada slurry tankers have large hydraulic brakes on all wheels for added security; lights for highway use; durable axle suspension – which prevents jolts and impacts travelling through the tank; swivel toe hitch – reduces jarring over uneven terrain and added safety in case tanker tips sideways; hydraulic park stent – for quick and easy hitching; parking brake; wide-angle PTO shaft. All Nevada slurry Tankers use large flotation tyres with good tread pattern for extra stability on the hills, and high resistance to puncture. Wide range of tyre options to best suit your needs.

The old days are over. New generation Nevada slurry tankers are available from 8,000 to 43,000 litre capacity for safe, fast, accurate effluent placement. So, for a fast, professional, and friendly service, contact the team at Nevada.

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields