- Sustainable Effluent Management

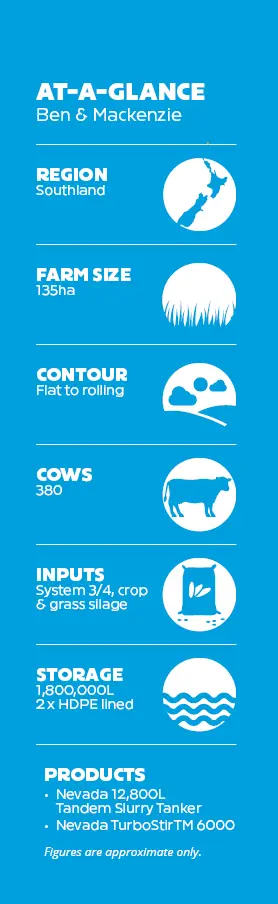

Prior to buying the Nevada Slurry Tanker, Ben and Mackenzie were using a hard hose cannon with an electric pond to irrigator pump. The irrigation system worked initially for their farm, but it was limited and only able to reach 70 hectares. Taking the approach of a hard hose took eight hours of labour to cover a 400 metre section that covered 120 cubic metres. By upgrading to Nevada, Ben says, “The cost analysis is looking great.” They can now deliver 300 cubic metres in the same amount of time, nearly tripling their capability.

Their previous effluent management system was only able to suck liquids from the pond, which left valuable nutrients in the solids behind. The shift to Nevada equipment saves them time, as well as delivers valuable nutrients across to further paddocks they could not reach before.

Mackenzie said, “Mum’s not complaining about stinking all her washing and clothes and having whites that aren’t exactly white anymore from filthy overalls.”

The process to set up the new system was fast and effective. With the product conveniently already in stock, Ben and Mackenzie were quickly set up with a Nevada 12,800L Tandem Slurry Tanker. The simplicity of operation with three hydraulic spools double acting on the tractor, one brake line, a fast 8in auto-fill arm, and no electronics, the slurry tanker is paired perfectly with a Nevada RainWave™ to dispense effluent across a 12 metre spread.

Their choice for a Nevada TurboStir™ 6000 is now able to mix the pond for better consistency of spread, ensuring nutrients are evenly distributed across the farm with minimal loss. With cows being fed on crop, baleage, and straw, the increase in yields benefit every aspect of their operations. Even after a few heavy days of rain, the slurry tanker can handle the terrain with ease without damaging the paddocks. “Having to just plug-in the hydraulic hoses in the back and running it off the joystick was a game changer for us,” Mackenzie said.

The benefits to their effluent management system were seen immediately with the increase in access to anywhere on the farm. They are no longer limited to where the initial irrigation lines were set up. Ben and Mackenzie are now able to manage three loads in a day with the Nevada Slurry Tanker that benefits nutrient value and saves them time.

“We would definitely recommend Nevada to anyone if they were looking to upgrade their system. They have been absolutely fantastic to deal with and we love their products,” said Ben. “Investing in the Nevada Tanker was a big win for us,” Mackenzie remarked, “You could customise your effluent system through Nevada to work perfectly for the farm or conditions you’re in, so 100% I would recommend it.”

At the end of the day, Ben and Mackenzie can throw their washing in much cleaner than before with Nevada not only changing their workload, but making the day easier for the whole family.

CASE STUDIES

Bringing you helpful advice, info, news and stories from Nevada. See how Nevada Group’s solutions have transformed dairy farms with increased efficiency and sustainability.

Receive fortnightly email newsletters with the latest insights from Nevada!

Copyright © 2025 Nevada Group

Receive fortnightly email newsletters with the latest insights from Nevada!

Copyright © 2025 Nevada Group

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields