- Sustainable Effluent Management

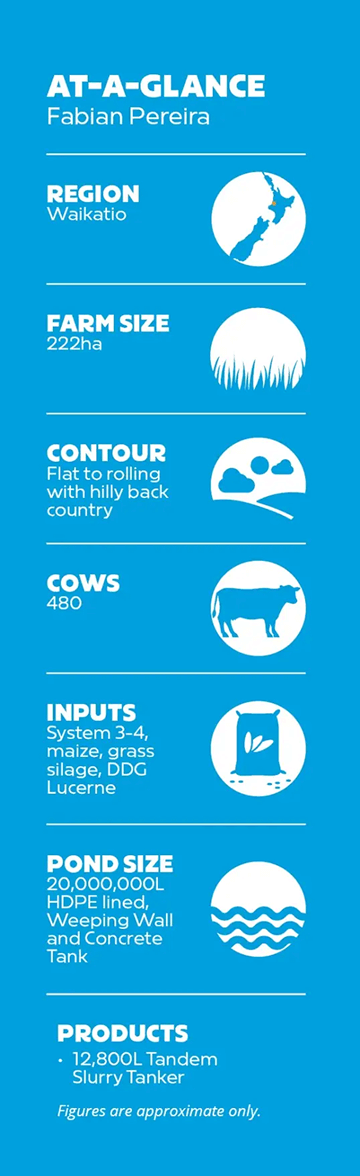

Kylie looks after all the milking and manages AI for calving while Fabian looks after the effluent management system that previously was a messy hassle of a task. Before switching to Nevada, the dairy effluent management system consisted of an old truck pump and an electric pump that ran to stationary or travelling cannons. The cannons were slow and time consuming to put into place. “It was an absolute nightmare as far as weather was concerned trying to get it out in time,” Fabian said. Spray drift was also a great challenge, which prompted a call from the neighbour asking for him to turn off the cannons due to the smell. In a need to finish the job, he offered the neighbour $100 for them to go out to dinner.

With compliance changes and the need for more capacity, Fabian decided to implement a 20 million litre pond with a weeping wall system and concrete tank. After not doing anything with the pond for two years, Fabian figured, “I would get myself a Christmas present and I told my wife I wanted a Nevada tanker.”

Fabian received a Nevada 12,800L Tandem Slurry Tanker that year for Christmas that could be filled via the concrete tank next to the weeping wall, which is gravity fed from the lined pond at the top of the hill. Fabian noted, “I’ve owned a Nevada tanker for 5 years now. It’s really low maintenance.” Only minor upkeep is needed and the RainWave™ attachment releases larger droplets that provide less wind drift. “I’ll drive around my house, my tenant’s house, I don’t have any issue and I haven’t had a complaint,” Fabian said. Even the others in the district noticed the spread pattern from a Nevada tanker was nicer than their tankers from other companies.

When asked why he chose a Nevada tanker, Fabian noted his father worked for a galvanising company in Australia years ago that informed the decision. His father said, “anything galvanised lasts.” The silver bullet of a tanker also offers an 8inch auto-fill arm function, which allows Fabian to stay in the tractor instead of managing messy irrigators. An additional benefit of the tanker is the ability to utilise the nutrients from effluent directly, instead of applying artificial nitrogen. With more reach to crop paddocks further away, Fabian has noticed the benefits in the maize and grass growth. “We had four years of drought in a row, some really hard summers, feeding constantly, so twice a day feeding,” Fabian said. To help with the drought, he would often spread effluent with the Nevada Slurry Tanker until two or three in the morning. “Some might say I was crazy, but we recovered a lot faster as soon as we got five millimetres of rain or anything like that. Our grass jumped out of the ground.”

Fabian is able to access 70% more of the farm with greater capacity to grow grass and increased days in milk. “I recommend Nevada slurry tankers to anyone,” Fabian said. It only takes three minutes to load and three minutes to unload, with the majority of the time spent travelling across paddocks. “I’m comfortable taking the tanker everywhere that I can get,” he said.

When asked what he thought of the Nevada Slurry Tanker, Fabian responded, “The Nevada tanker was number one for me, love it.”

CASE STUDIES

Bringing you helpful advice, info, news and stories from Nevada. See how Nevada Group’s solutions have transformed dairy farms with increased efficiency and sustainability.

Receive fortnightly email newsletters with the latest insights from Nevada!

Copyright © 2025 Nevada Group

Receive fortnightly email newsletters with the latest insights from Nevada!

Copyright © 2025 Nevada Group