- Sustainable Effluent Management

Understanding how pond layout, inflow points, and operating depth affect pond stirrer efficiency helps farmers avoid crusting, maximise the holding capacity of your effluent storage, reduce downtime, and achieve more predictable nutrient application.

Effluent ponds naturally separate over time. Heavier solids settle to the bottom, while lighter material rises, and crusting can form on the surface. Without effective mixing, nutrients become unevenly distributed, leading to inconsistent slurry quality and reduced value at spreading time.

Correct stirrer placement ensures solids are re-suspended evenly throughout the pond. This improves nutrient consistency, reduces blockages during pumping, and supports compliance by maintaining the capacity of your effluent ponds. Positioning also affects how efficiently energy is used, as a well-placed stirrer achieves better mixing without excessive run time.

The best outcomes depend on how effectively the stirrer moves and mixes the entire volume of effluent in the pond. Efficient stirring is not about creating surface turbulence alone. The goal is to generate circulation that reaches settled solids, breaks up crusts, and maintains a uniform slurry from top to bottom.

Great performance is influenced by several factors, including the depth, shape, inflow and outflow locations, propeller depth, and operating angle. A stirrer that is positioned too shallowly may only agitate the surface, while one placed incorrectly in relation to the pond walls may create dead zones where solids remain untouched.

One of the most common mistakes is positioning a stirrer too close to the inflow or outflow. Effluent entering the pond creates natural movement, but relying on this alone leads to uneven mixing.

For best results, position the stirrer so it works across the main body of the pond rather than directly beside the inflow pipe. This allows you to pull material from across the pond and circulate it back through the centre. If the stirrer is placed too close to the outlet, solids may not be fully mixed before pumping begins, increasing the risk of blockages and uneven nutrient delivery.

Spacing the stirrer away from both inflow and outflow points helps maintain consistent slurry quality throughout the pond.

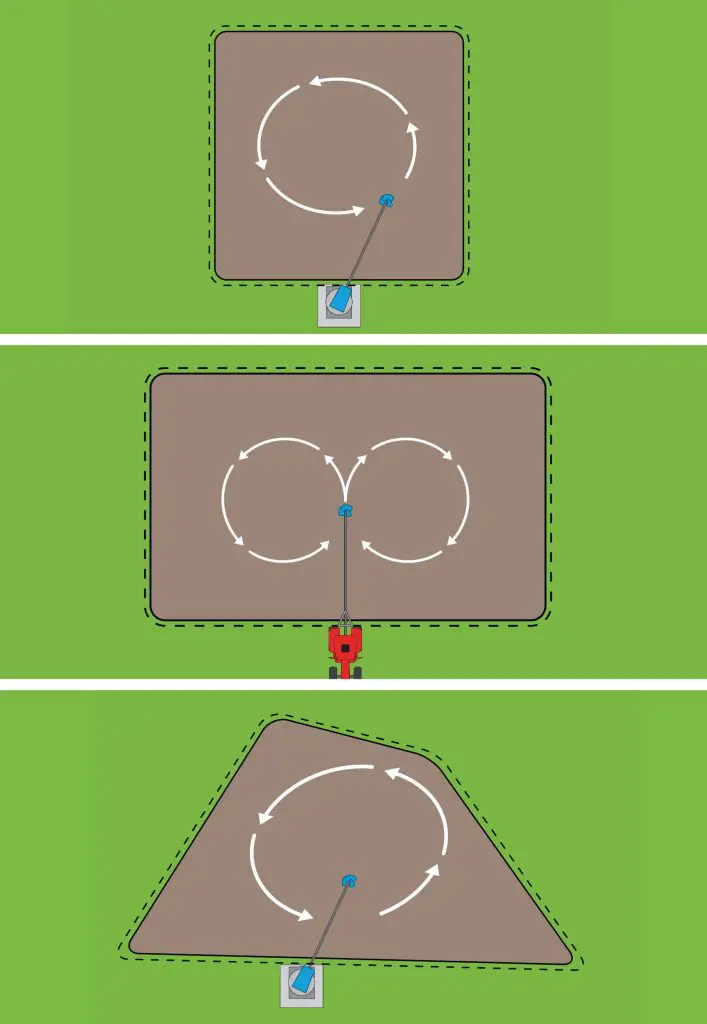

Pond shape directly affects how effluent circulates during mixing. Square and rectangular ponds behave differently from circular or irregular ones.

In rectangular configurations, stirrers are often best positioned along the long side, angled slightly towards the centre. This encourages a rolling motion that travels the length of the pond, drawing settled material back into suspension.

In square ponds, central placement along one side can be effective, provided the angle is adjusted to reach opposing corners. The aim is to avoid corners becoming stagnant zones where solids accumulate over time.

Where ponds are irregular in shape, placement should focus on targeting known problem areas, such as deeper sections or areas where solids historically settle.

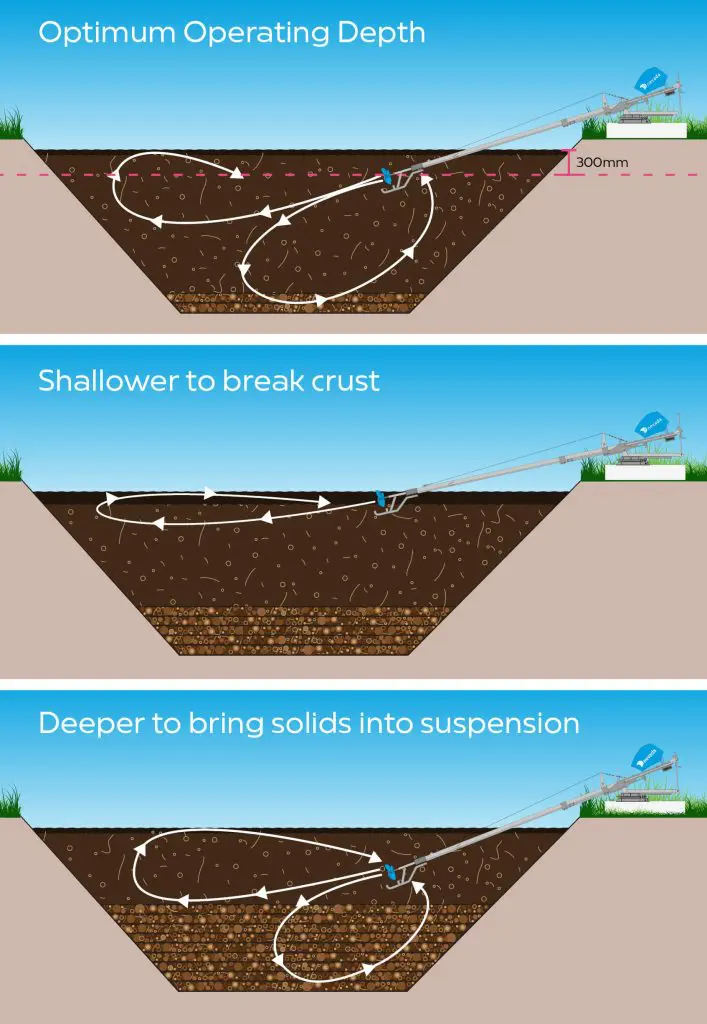

Depth is one of the most important factors in achieving reliable outcomes. Running the unit too high tends to disturb only the surface, while running it too deep can reduce circulation and place unnecessary strain on equipment.

A common guideline is to position the propeller approximately 300 mm below the slurry surface. At this depth, you will generate strong horizontal movement while still pulling solids up from lower levels. Visual indicators, such as a vortex or rolling motion on the surface, often confirm the correct depth.

If a surface crust has formed, a slightly shallower position helps break it up before returning to the optimal depth. If solids have settled heavily to the bottom, temporarily lowering the angle of the stirrer allows them to be reintroduced into the mix, helping break down the solids for an even spread.

Even with correct placement, over-stirring or under-stirring can reduce performance outcomes. Many farms benefit from shorter, regular mixing cycles rather than long, infrequent runs. Consistent daily mixing helps maintain a uniform slurry and prevents solids from compacting over time.

Using timers or automated controls supports steady operation and reduces the risk of excessive wear. When positioning the stirrer, ensure it can operate safely and consistently at the chosen depth without requiring frequent adjustment.

Different types suit different pond layouts and operational needs. Electric pond stirrers are often positioned permanently and work well for ongoing maintenance mixing. PTO-driven stirrers offer flexibility and are useful when access points vary or when ponds are shared across multiple locations.

Regardless of type, correct placement remains critical. A well-designed system considers how the unit interacts with pond geometry, inflow patterns, and spreading schedules to support efficient downstream operations such as pumping or umbilical systems.

Several issues repeatedly arise on farms struggling with mixing performance:

Addressing these issues improves reliability and reduces time spent dealing with blockages or uneven spreading results.

Achieving consistent mixing is not about running a stirrer harder or longer. It is about placing it correctly and operating it with intent. By considering inflow locations, pond shape, depth, and run timing, farmers can significantly improve performance, reduce equipment wear, and improve nutrient consistency.

Small adjustments in positioning often deliver noticeable improvements across the entire effluent system.

If you want confidence that your stirrer is positioned correctly and delivering reliable results, the team at Nevada can help. With our extensive experience designing and supplying effluent mixing systems for New Zealand conditions, we can assess your pond layout and recommend a setup that supports efficient mixing and dependable spreading. Get in touch today to discuss your pond configuration.

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields