- Sustainable Effluent Management

Giving the outside of the slurry tanker a regular clean will help in noticing any issues like corrosion or leaks. These are the kind of issues that start off small but left unattended can turn into big problems.

Nevada slurry tankers have a clear coating over the galvanisation, so cleaning is easy and can usually be done with a high-pressure hose like you’d use to wash out the cow shed.

If your slurry tanker is painted, more care may need to be taken to ensure paint doesn’t chip off if using a high-pressure hose or water blaster. Any exposed, un-galvanised steel on the tank should be repainted to prevent corrosion and maintain the integrity of the tank.

The inside of the tank requires less cleaning and can usually be done on an annual basis. With a Nevada auto-filling slurry tanker the effluent loads from the front of the tank and is pushed to the back minimising the amount of sand and debris dropping out of suspension and accumulating in any crevices. Tankers that load from the side may require a more regular clean as there is a higher chance of sand accumulation.

Every joint and moving part, especially pivots and rotating parts, needs grease to keep them lubricated and reduce wear. Particular attention should be paid to the axle and steering components, which should be greased weekly. The 8″ rotating joint on your auto-filling arm is very important as it not only lubricates but also seals the part to prevent effluent and other corrosive materials from getting in. This joint should also be greased weekly. The grease nipple is located on the bottom side, and grease should be pumped until it is seen coming out of the breather hole on the top.

O rings that seal the couplings of suction hoses need to be checked regularly, as leaks will slow down loading time. These O rings are easily popped out and replaced where necessary.

The vacuum pump is designed to use oil, so this should be monitored to ensure the oil is dropping through at the correct rate. Vacuum pump oil and oil droppers are available when needed.

Vacuum pump vanes are the other thing to be aware of. If you notice your slurry tanker is taking longer to load than usual this could be a sign the vanes are worn and need repair or replacement. If you suspect this is the case, just give the Nevada service team a call and they can help diagnose the issue. Repair kits are available for most makes and models of slurry tanker.

Pressure release valves and vacuum relief valves should always be operating properly and within their parameters (-0.5 Bar, +0.66 Bar), as they protect both the tank and pump from damage. These valves should be monitored regularly, as failure of either increases the risk of implosion. Replacement relief valves are available for most makes and models of slurry tanker.

To be sure your release valves are working the vacuum gauge needs to be working! If not, you can buy a replacement part here.

The moisture trap on the suction line, located between the vacuum tank and pump, needs to be emptied regularly to maintain optimal performance. It is recommended to leave the drain valve open when the machine is parked for an extended period of time.

Suction hoses can get squashed or flattened, restricting air or fluid flow, slowing filling time, and potentially causing excessive wear on the pump. Once hoses are flattened, they will not hold their original shape and must be replaced.

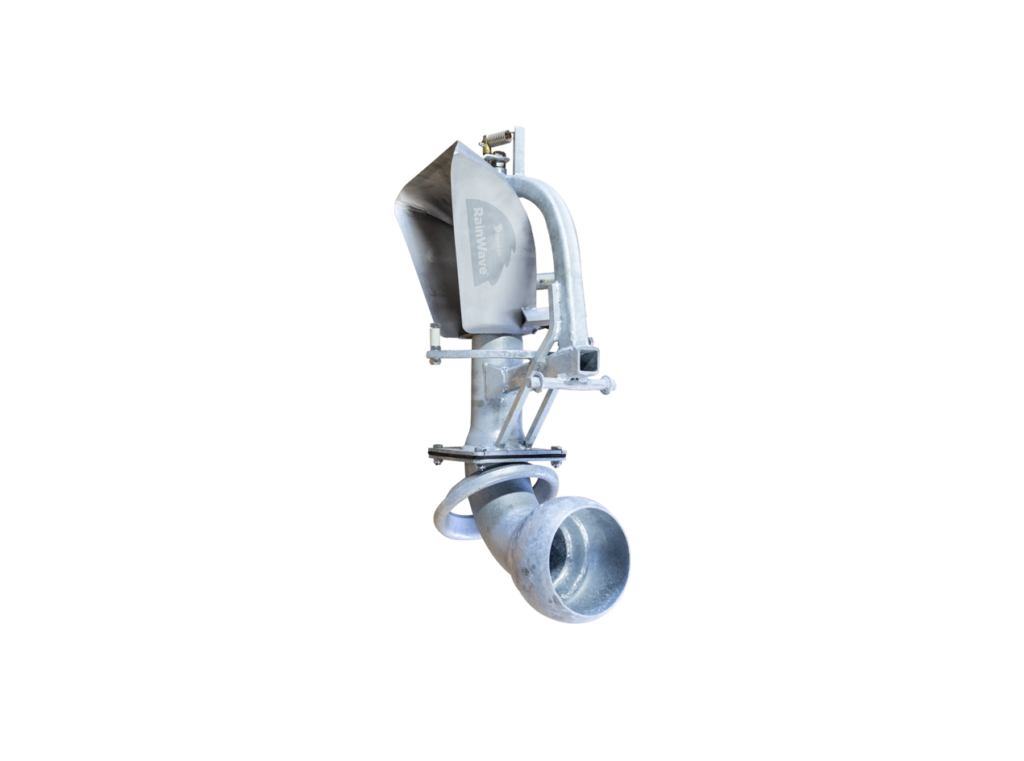

Regularly check your RainWaveTM applicator(s) for excessive wear in all the pivots by giving them a wiggle to ensure nothing is excessively loose. This could be a sign of fatigue in the spring or wear on the bushes. Ensure the top over-centre spring is in place and in good condition, as this is critical for achieving an even spread with the RainWaveTM. Repair kits are available for all the wear parts of a RainWaveTM.

Regularly check tyre pressures and wheel nuts. Wheel nuts should be visually checked before each use by the wheel nut indicator arrows. Wheel nuts on Nevada tankers should be torqued to 480Nm and tyres at 60PSI.

Lastly, let’s not forget about health & safety – check your tyres for wear and make sure the lights are working!

Need more advice or help with your service, give our team a call…

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields