- Sustainable Effluent Management

Different makes and models of slurry tanker will include different loading arms.

Nevada slurry tankers include a 8in Ezi-Load auto-filling arm on models 10,000L and up, and this is an optional feature for smaller models.

While the Ezi-Load filling arm suits most farmers and contractors, Nevada slurry tankers can also be fitted with a Side filling Arm or Dorsal Boom loading arm.

Nevada includes the Ezi-Load filling arm as a standard feature because it is the best option for most situations. It is simple to use, requires minimal maintenance, and everything works automatically – all the things most farmers and contractors enjoy.

The Ezi-Load filling arm is 8” in diameter, allowing for filling at almost twice the speed of the standard 6” manual loading. A ball at the end of the arm inserts into a rubber coned filling station providing a better seal and improved suction.

All hydraulic functions are synchronised. This means when the arm is lowered, the vacuum pump is switched to vacuum and the gate valve is opened – all with one lever. For even more speed, there is an optional push-button control. The push button control allows for the tank to be under vacuum before the gate valve is open, cutting up to a minute off your loading time.

Another option for speeding up loading time is a loading accelerator pump. This is a hydraulically driven pump attached to the end of the loading arm which forces the fluid into the tank. This is available for all sizes of slurry tanker, but the advantages are really seen on larger models.

The side filling arm is ideal for farmers and contractors who change filling locations frequently. With a side filling arm, you’re able to reach further, meaning you can easily suck directly from a pond or sump without the need for a filling station.

Like the Ezi-Load filling arm, the Side filling arm is a standard 8” diameter for fast loading. There is also the option of a 10” diameter, or a loading accelerator pump to supercharge loading times.

With a side loading arm, a rotating swivel joint at the top allows for easy angle adjustment and reach into ponds and sumps. It can also be used for sucking out of above ground tanks, however if this is your main usage a dorsal boom may be a better option.

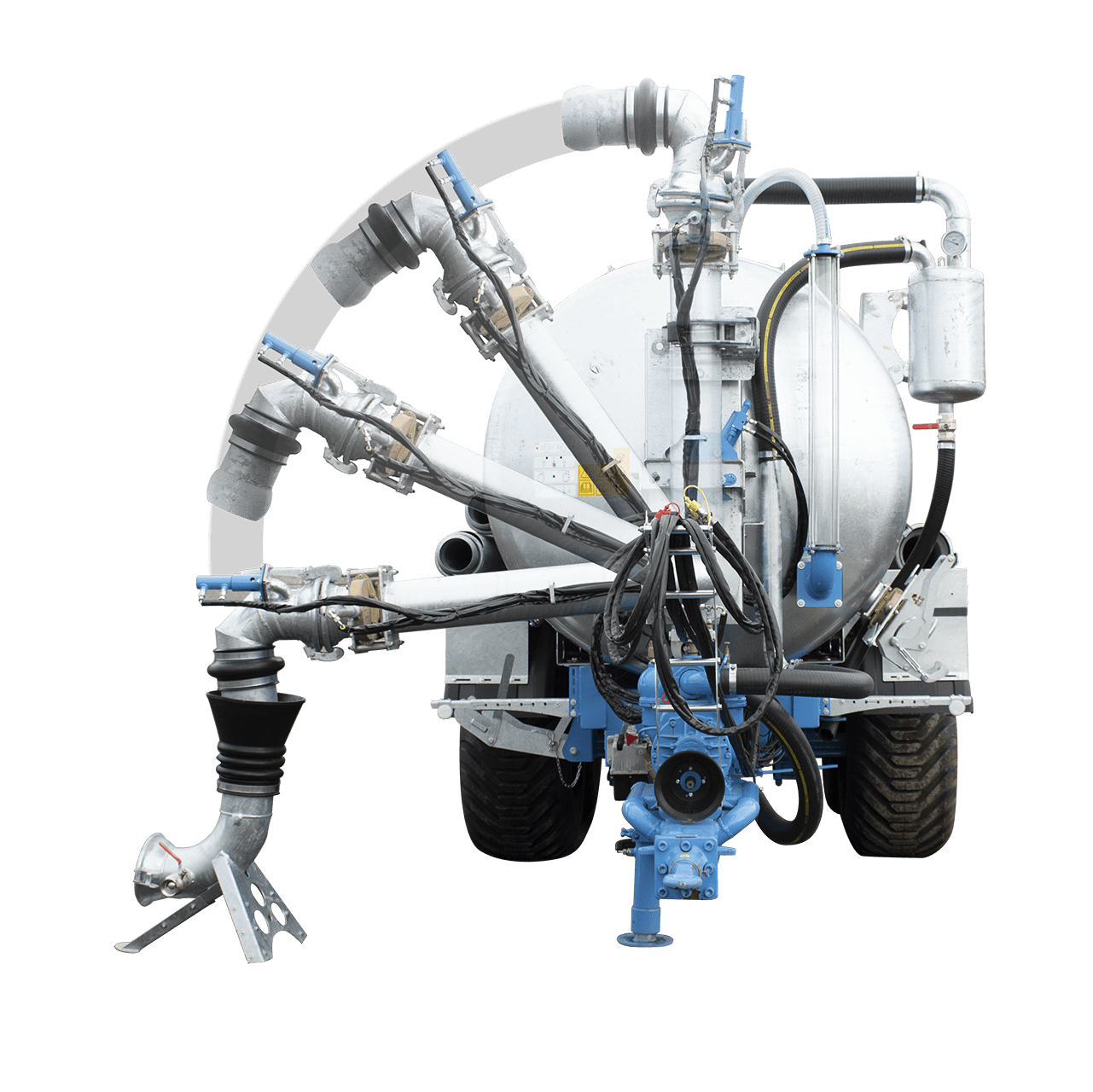

A dorsal boom, or double-jointed filling arm is ideal for reaching into above ground tanks or out to ponds to suck up without the need for a hose and easel. The 8” loading arm is mounted on top of the tank to provide the additional height required.

As with other loading arm options, a loading accelerator pump can be fitted to the dorsal boom to speed up filling times.

Choosing the right loading arm for your slurry tanker can make all the difference in ensuring a smooth and efficient filling process. If you’re looking for speed and convenience, the standard Ezi-Load auto-filling arm is a good fit for most farmers and contractors. Its simple design, minimal maintenance requirements, and automatic functions make it simple and easy to use. Plus, with an 8″ diameter, you can fill your tank almost twice as fast as with standard manual loading.

If you frequently change filling locations or need to access above ground tanks, you may want to consider the Side filling arm or Dorsal Boom loading arm instead. With the Side filling arm, you’ll be able to reach further and suck directly from ponds or sumps without needing a filling station. And with the Dorsal Boom loading arm, you’ll have the height needed to access above ground tanks without the need for a hose and easel.

Ultimately, the key is to choose the loading arm that fits your specific needs and preferences. By taking the time to consider your options and select the right arm, you can save time and increase productivity when filling your slurry tanker. We hope this guide has been helpful in making your decision, and if you have any further questions, don’t hesitate to reach out!

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields