- Sustainable Effluent Management

An overheated pump can halt productivity and lead to significant expense, so read on to follow our tips and recommendations for avoiding overheating your slurry tanker pump.

As the metal heats up past ideal levels, it expands, and the vanes seize in the body of the pump (the rotor seizes in the bore). If you’re lucky, this will be repairable with just a few vanes breaking; however, the more likely outcome is a broken block, which usually comes under the ‘not worth repairing’ category. This is costly and avoidable.

Generally, overheating is caused by overworking the pump. If your vacuum pump isn’t running at optimal levels, you may end up running it for longer or at higher speeds, which can cause the pump to overheat and potentially seize. Other reasons include:

Thick or Inconsistent Slurry: If the slurry mixture is too thick or inconsistent, it can place more strain on the vacuum pump. A good stir before use ensures the slurry is at an ideal consistency, preventing unnecessary strain on the pump.

Insufficient Cooling: Slurry pumps need proper cooling to function effectively. If the tank is continuously used with little to no rest between cycles, the pump doesn’t get enough time to cool down, leading to overheating.

Incorrect Suction Pipe Size: Using a suction pipe that’s too small can restrict the flow of slurry, making the pump work harder to move the material. A larger suction pipe (typically 8”) reduces restrictions and helps prevent the pump from overheating.

Leaks in the System: Leaks can reduce the efficiency of the vacuum pump, forcing it to run longer or harder to compensate. Regular checks for leaks and timely repairs are necessary to avoid pump strain.

Improper Oil Levels or Type: Using the wrong type or an insufficient amount of oil in the vacuum pump can result in inadequate lubrication, leading to increased friction and heat buildup. Always use the recommended oil at the correct rate to ensure smooth operation.

Exceeding Duty Cycles: Every vacuum pump has a specific duty cycle, indicating how long it can run at full capacity before requiring a rest. Ignoring this cycle and running the pump beyond its limits can cause overheating and permanent damage.

Start by giving your slurry a good stir before using the vacuum pump to suck it up. Aim for a consistent slurry mix that’s not too thick.

Tip: When spreading constantly over close paddocks, keep an eye on the pump’s temperature. Spreading over paddocks closer to your effluent storage means the vacuum pump will be getting less rest/cooling time between sucking up and pumping out.

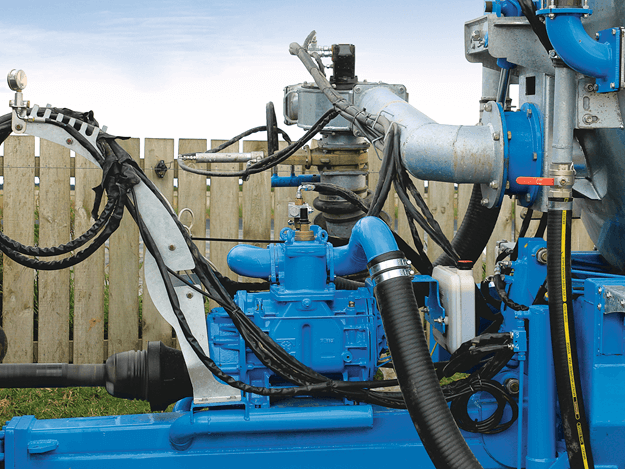

Recommendations: In addition to the best practices listed above, if you’re in the market for a new slurry tanker or replacing your slurry tanker vacuum pump, we also recommend considering vacuum pumps with air induction cooling and long-life vanes.

Air induction cooled vacuum pumps have been the best practice standard for Nevada slurry tankers since the end of 2018. This new technology significantly extends the duty cycle of the pump, enabling it to operate continuously at 80% vacuum. These are a must-have for slurry tankers with a capacity of 10,000L and larger.

Also, ensure your pump has an ICP (Integrated Crash Protection) system. An ICP system allows the rotor to spin freely, meaning that in the unlikely event your rotor did seize, it would simply move out of alignment, avoiding damage to the housing.

To ensure your slurry tanker operates at peak performance, it’s essential to invest in the right equipment and implement effective maintenance practices. If you’re considering upgrading your slurry tanker or vacuum pump, contact Nevada today for expert advice and high-quality solutions tailored to your needs.

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields

"*" indicates required fields